-

Galvanized Steel Pipes And Fittings

Galvanized steel pipe is widely used in construction, machinery, coal mine, chemical industry,electric power, railway ,highway, container, sports facilities, agriculture machinery, petroleum machinery, mining machinery and other manufacturing industries. Galvanized steel pipe with hot dip galvanized layer of welded steel pipe surface can increase the corrosion resistance of steel pipe its service life. Galvanized pipe's usage is very wide, in addition to a general low pressure fluid such as water, gas, oil line pipe, also used as oil industry, especially the ocean oil file oil well pipe, oil pipe.

-

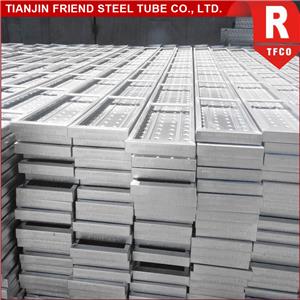

Line Pipes Galvanized For Construction

Galvanized steel pipe surface is hot dip galvanized, galvanized surface is very uniform, can increase the corrosion resistance, extend the service life. Galvanized pipe usage is widely, in addition to a general low pressure fluid such as water, gas, oil line pipe, also used as oil industry, especially the ocean oil field oil well pipe, oil pipe, chemical coking equipment of oil heater, the condensing, trestle pile, scaffolding pipes and frame tube for construction, etc.

-

Threading Galvanized Steel Pipes With Couplers

The process of thread&screwed treatment : The manufacture of pipe hoops is the most delicate, is the focus of the whole product, because it is the whole project, is the part of a large amount of pressure.The material requirement of tube hoop is higher than or equal to the material of seamless steel tube itself.After the round steel is blanked, the size is fixed by lathe processing, then the thread is processed, and finally the thread and size are tested.

-

HDG Galvanized Steel Pipes China Factories

Galvanized steel is a kind of special steel material. It USES special technology to combine the elements of zinc and iron to produce a brand new galvanized steel material.Many excellent features of galvanized steel, hot galvanized steel coating uniform, strong adhesion, so the service life will be very long。 Galvanized steel composition Iron is the main component of steel. The difference between iron and steel is the difference in carbon content. Iron has lower carbon content, so it has better toughness and hardness。

-

ASTM A53 GrB Galvanized Pipes For Gas And Water

Seamless Pipe : 1. The tube billet shall be rolled for three consecutive rolls at first, and the diameter test shall be carried out after extrusion. If the surface does not respond to the crack, the round tube shall be cut by the cutting machine. 2. Then enter the annealing process. During annealing, acid liquid should be used for pickling. 3. After the quality inspection, it shall be strictly selected by hand by the staff, and the surface shall be coated with oil after the quality inspection. 4. If the hole diameter is too large, it shall be straightened. After straightening, it shall be sent to the flaw detector by the transport device for flaw detection experiment, and finally it shall be labeled and placed in the warehouse after specification arrangement.

-

Screwed Galvanized Steel Pipes

Steel pipe is divided into two types: Thread tube coupling, Connect the pipe with tool joint by butt welding. Oil drilling pipe (yb528-65) is a seamless steel pipe used for both ends of oil drilling for internal or external thickening.Steel pipe is divided into two types, Screwed and non-screwed. Seamless steel tube: round tube billet heating perforation punching annealing pickling coating (copper plating) multiple cold drawing (cold rolling) billet tube heat treatment straightening hydraulic test (flaw detection) marking warehousing.

-

Galvanized Water Pipe & Steel Plumbing

The benefits of Hot-dipped surface treatment : Durability: in a suburban environment, the standard galvanized rustproof thickness can be maintained for more than 50 years without repair; 2 in urban or offshore areas, the standard hot dip galvanized rust protection layer can be maintained for 20 years without repair; 3, good reliability: zinc coating and steel is metallurgical combination, become a part of the steel surface, so the durability of the coating is more reliable;

-

Water Supply Galvanized Steel Pipes

Hot-Dipped Galvanized steel pipe Application : It is widely used in curtain wall materials, steel structure engineering, installation engineering, electric power facilities, traffic facilities, civil buildings, highway Bridges, mechanical coal mines, metallurgy and chemical engineering and many other aspects.In use, it can be used not only as a pipe for water, gas, oil and other general low-pressure liquid, but also as a pipeline for oil Wells in the petroleum industry, heaters, exchangers and other pipes for chemical equipment, as well as supporting pipes for bridge pipe piles and tunnel tunnels.

-

Galvanized Water Pipes and Plumbings

The biggest role of hot galvanizing is to prevent the object rust, as we all know, no matter what product rust will reduce its service life, rust corrosion of the object's own material speed is particularly fast, so after hot galvanizing, the product will not rust, naturally increase the product's use time.Object galvanized after the product will be more beautiful, and not galvanized surface uneven color is not good, zinc is silver, so galvanized after the product looks more clean, beautiful. The unique advantage of hot galvanizing is that it is more environmentally friendly and pollution-free for the environment, and it costs less, and save time and labor, to provide people with more time, energy and money.