Views: 0 Author: Site Editor Publish Time: 2025-12-01 Origin: Site

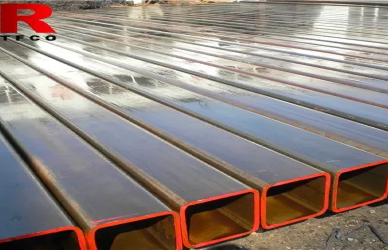

RSH (Rectangular Steel Hollow) and SHS (Square Steel Hollow) steel tubes are essential components in various sectors like construction, infrastructure, and engineering due to their superior strength and versatility. However, a significant challenge these tubes face is corrosion, which can considerably shorten their lifespan and degrade their performance. Corrosion occurs when steel is exposed to moisture, chemicals, or temperature fluctuations, leading to rust and material degradation. This article focuses on the importance of corrosion resistance in maintaining the durability and reliability of RSH/SHS steel tubes, especially in environments exposed to harsh conditions. It also highlights the protection methods, such as galvanization, coatings, and regular maintenance, that help enhance the longevity of these tubes. Understanding how to address corrosion through these protection measures is crucial for selecting the most suitable materials for sustainable, long-lasting applications in construction and engineering.

Steel, used in RSH (Rectangular Steel Hollow) and SHS (Square Steel Hollow) tubes, is an alloy of iron with carbon and other elements. While steel is strong, it is susceptible to corrosion, especially in environments with moisture, salts, or chemicals. Corrosion occurs when steel reacts with oxygen and moisture, forming iron oxide (rust), which weakens the material and reduces its lifespan. Steel’s vulnerability to corrosion is particularly high in moist, salty, or chemically active environments, accelerating the deterioration process.

Several factors affect how quickly steel tubes corrode:

Environmental Exposure: Humidity, salt (such as in coastal areas), and chemicals like acids or industrial pollutants can speed up corrosion. Temperature variations also contribute, as frequent heating and cooling can break down protective layers, allowing moisture to penetrate.

Material Composition: Different steel alloys enhance corrosion resistance. For example, adding chromium and nickel creates a protective layer that prevents oxidation. Stainless steel alloys, with higher chromium content, are particularly resistant to corrosion, making them ideal for harsh environments.

Corrosion resistance is essential for maintaining the structural integrity and safety of RSH/SHS steel tubes. Corrosion-resistant tubes last longer, requiring fewer replacements, and reducing maintenance costs and material waste. This is especially important in outdoor or industrial settings, where steel tubes face constant exposure to harsh conditions. Durable, corrosion-resistant tubes contribute to the long-term reliability of infrastructure projects, supporting sustainability by reducing the need for repairs and minimizing environmental impact.

RSH (Rectangular Steel Hollow) and SHS (Square Steel Hollow) steel tubes are commonly used in various structural applications, but their corrosion resistance is critical to ensuring long-term performance. Several protection measures are employed to enhance their durability and resistance to environmental factors.

Hot-Dip Galvanizing: In this process, RSH/SHS steel tubes are submerged in molten zinc, which forms a protective zinc coating on the surface of the steel. This coating acts as a barrier, preventing moisture and chemicals from reaching the steel surface, thus protecting the steel from rust and corrosion.

Benefits of Galvanized Steel Tubes: The zinc coating provides long-term protection against environmental elements such as humidity, salts, and pollutants. Galvanized steel tubes are especially suitable for outdoor use or in harsh environments, where they can withstand exposure to corrosive agents for extended periods, often lasting 20 to 50 years with minimal maintenance.

Epoxy Coatings: Epoxy coatings are applied to RSH/SHS steel tubes to provide an additional layer of protection against moisture, chemicals, and abrasion. These coatings bond tightly to the surface, offering excellent corrosion resistance and increasing the tube's lifespan, particularly in harsh or industrial environments.

Powder Coating: Powder coating is another effective way to protect steel tubes. The powder is applied electrostatically and then cured under heat to form a durable, protective layer. In addition to improving corrosion resistance, powder coatings offer aesthetic benefits by providing a range of colors and finishes, making it ideal for applications where appearance matters as well as performance.

Use of Stainless Steel: Stainless steel is naturally resistant to corrosion due to the high content of chromium in its composition, which forms a passivating layer that prevents rust and corrosion. RSH/SHS tubes made from stainless steel offer excellent resistance to a variety of environmental factors, making them ideal for corrosive environments like marine or chemical industries, without the need for additional coatings.

Alloying for Enhanced Corrosion Resistance: Adding elements such as chromium, nickel, and molybdenum to steel improves its corrosion resistance. These alloys enhance the natural protection against rust by forming an invisible protective layer on the surface, which makes RSH/SHS tubes more durable in aggressive environments. Alloying is often used when high resistance to chemical exposure and moisture is required.

Cathodic Protection: This method involves using an external current to make the steel tube the cathode of an electrochemical cell, preventing corrosion by ensuring that the steel does not undergo oxidation. Typically used for underground or submerged structures, sacrificial anodes (such as zinc or magnesium) are placed near the steel tube. These anodes corrode in place of the steel, providing protection against rust and degradation. This method is especially effective in pipelines, tanks, and other large-scale infrastructure.

To ensure the long-term durability and corrosion resistance of RSH (Rectangular Steel Hollow) and SHS (Square Steel Hollow) steel tubes, it is essential to implement regular maintenance and protective measures. Routine inspections, timely reapplication of coatings, and proper cleaning practices are crucial to maintaining the effectiveness of corrosion protection and extending the tubes’ service life.

Routine inspections are vital for detecting early signs of corrosion or damage to protective coatings. Over time, environmental factors like moisture, chemicals, and physical wear can gradually deteriorate the protective layers. Regularly checking for cracks, peeling, or abrasions in the coating can help identify areas where corrosion may begin. Inspections should focus on areas most exposed to harsh conditions, such as joints, welds, and areas near the ground or water. Early detection of damage allows for timely repairs or touch-ups, preventing more extensive corrosion and costly replacements.

Protective coatings like galvanizing, epoxy, and powder coatings provide essential corrosion resistance, but they are not permanent. Over time, these coatings can wear down due to environmental exposure, physical damage, or aging. It is important to reapply these coatings at regular intervals to maintain their effectiveness. The timing of reapplication depends on factors such as the environmental conditions, type of coating, and the level of exposure to harsh elements. For example, galvanized coatings may last 20 to 50 years, but high-traffic or coastal areas may require reapplication sooner. Epoxy coatings may need to be refreshed every few years, especially if subjected to constant moisture or chemicals. Regular monitoring ensures that the tubes continue to perform optimally in protecting against corrosion.

Proper cleaning and maintenance are key to preventing the buildup of materials that could accelerate corrosion. Dirt, salt, and chemicals can accumulate on the surface of RSH/SHS steel tubes, especially in environments like coastal regions or industrial areas. These substances can compromise the protective coatings and lead to rust formation. To avoid this, regular cleaning using mild detergents and non-abrasive brushes is recommended. Care should be taken to avoid harsh cleaning methods that could damage the protective layers. In addition, debris removal from areas where moisture may accumulate (such as joints or under the tubes) helps prevent corrosion hotspots. Routine cleaning ensures the integrity of the coating and minimizes the risk of corrosion.

Answer: Corrosion in RSH/SHS steel tubes is primarily caused by exposure to moisture, salt, chemicals, and temperature fluctuations. These environmental factors accelerate the oxidation of steel, leading to rust and degradation of the material over time.

Answer: The galvanization process provides long-term corrosion protection, typically lasting 20 to 50 years, depending on the thickness of the zinc coating and the environmental conditions the steel tubes are exposed to.

Answer: Without protective coatings, RSH/SHS steel tubes are highly susceptible to corrosion in corrosive environments, such as marine or industrial settings. Protective measures like galvanizing, coatings, or using stainless steel are recommended for durability.

Answer: Regular inspections are crucial to detect early signs of damage or corrosion. Over time, galvanized steel may require re-coating if the zinc layer wears off, and it is essential to clean the tubes periodically to remove any corrosive materials like dirt, chemicals, or moisture that can affect their longevity.

The corrosion resistance of RSH (Rectangular Steel Hollow) and SHS (Square Steel Hollow) steel tubes is vital for their performance and longevity in a wide range of applications. Without proper protection, exposure to harsh environmental factors can cause these steel tubes to deteriorate, compromising their structural integrity. Measures such as galvanization, coatings, and consistent maintenance are key to prolonging the life of steel tubes and ensuring their continued reliability. Galvanized coatings and protective layers shield the steel from corrosion, while regular inspections and cleaning help maintain their protective properties. When selecting materials for construction and engineering projects, it’s crucial to prioritize corrosion-resistant solutions to guarantee durability, reduce long-term maintenance costs, and enhance overall project sustainability. By choosing corrosion-resistant materials, you ensure the success and resilience of your infrastructure in the long run.