Views: 169 Author: Site Editor Publish Time: 2025-09-04 Origin: Site

In the world of modern construction and structural engineering, the selection of materials plays a critical role in determining the safety, efficiency, and longevity of buildings and infrastructure. Among the many options available, Square Hollow Structural Sections (SHS) have emerged as a highly reliable choice for load-bearing and framing systems.

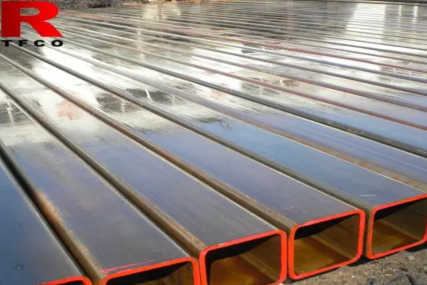

SHS, sometimes referred to as square hollow steel sections, are hollow, tubular steel members with a square cross-section. Their unique geometry, combined with the inherent strength of steel, provides several advantages over conventional solid beams or rectangular sections. These benefits make SHS a preferred choice in both residential and commercial construction, as well as industrial frameworks.

This article explores the key advantages of SHS for load-bearing and framing systems, their structural performance, practical applications, and why they are increasingly favored by engineers and architects around the world.

SHS steel sections are manufactured through hot-rolled or cold-formed processes, resulting in hollow square tubes with uniform wall thickness and high precision. Unlike solid sections, the hollow geometry provides a high strength-to-weight ratio, making SHS both lightweight and strong.

The square shape also simplifies connection design, allowing for easier welding, bolting, and integration into modular frameworks. This versatility makes SHS ideal for:

Columns and vertical load-bearing supports

Horizontal beams in floor and roof structures

Modular frames for industrial and commercial buildings

Architectural frameworks where aesthetics and functionality intersect

By combining structural efficiency with design flexibility, SHS steel sections contribute to safer, more cost-effective, and visually appealing construction.

One of the primary benefits of SHS is its efficient use of material. The hollow square shape allows engineers to achieve the same load-bearing capacity as solid steel members while using less material. This results in:

Reduced overall structure weight, lowering foundation and support requirements

Easier handling and installation on-site

Potential cost savings without compromising structural integrity

The square geometry of SHS ensures that stresses are distributed evenly along all sides, reducing the likelihood of weak points that can lead to localized failures. This uniformity enhances the resistance to bending, torsion, and axial loads, making SHS particularly suitable for columns and vertical supports in multi-story buildings.

Buckling is a common concern for slender structural members subjected to compressive loads. SHS steel sections have higher buckling resistance compared to rectangular or flat sections of equivalent weight due to their closed geometry. This allows engineers to design slender yet stable columns, optimizing both space and material usage.

Unlike open sections such as I-beams or channels, the closed, hollow square cross-section provides excellent torsional rigidity. This property makes SHS ideal for lateral framing, cantilevered beams, and truss applications, where uneven loads or twisting forces may occur.

SHS steel sections are highly durable and can withstand corrosive environments when properly coated or galvanized. Their hollow design minimizes the risk of cracking and fatigue under cyclic loading, ensuring long-lasting structural performance in industrial, commercial, and residential projects.

In addition to load-bearing applications, SHS provides numerous benefits in framing systems for buildings and industrial structures:

The uniform square shape of SHS simplifies the creation of modular and prefabricated frames. Engineers can easily design repeatable units for factories, warehouses, or residential projects, which reduces construction time and labor costs.

SHS allows for simple welding, bolting, and mechanical fastening. The flat surfaces make it easier to attach plates, brackets, and other structural components compared to circular or I-shaped sections. This facilitates the creation of complex frameworks without compromising stability.

From trusses to bracing systems, SHS can be used in horizontal, vertical, or diagonal orientations, offering flexibility in architectural and structural design. Its aesthetic appeal also makes it suitable for exposed structural frameworks, such as modern commercial facades or interior beams.

Because of their hollow geometry, SHS members are lighter than solid steel sections of equivalent strength. This reduces transportation and handling costs while allowing designers to create slender, elegant structural members that do not compromise load capacity.

The closed geometry of SHS provides multi-directional stiffness, which contributes to the overall stability of the structure. In areas prone to seismic or wind loads, SHS framing systems enhance resistance to lateral movement and twisting, improving safety for occupants.

SHS steel sections are widely used across different industries due to their versatility and structural performance:

Used for columns, beams, and floor framing, SHS provides both strength and flexibility in design. Its uniform geometry allows for open-plan layouts with fewer supports, creating spacious interiors.

SHS is suitable for load-bearing columns, balcony supports, and roof frameworks in residential buildings. Its high strength-to-weight ratio allows for lighter foundations while maintaining safety and stability.

Factories, warehouses, and production facilities utilize SHS for roof trusses, conveyor supports, and storage racking. The hollow sections reduce weight without sacrificing structural capacity, allowing for longer spans and open workspaces.

SHS can be integrated into pedestrian bridges, small vehicular bridges, and modular infrastructure projects. Its torsional rigidity and buckling resistance make it ideal for supporting dynamic loads from traffic and environmental forces.

The clean lines of SHS steel sections are ideal for visible structural elements, including atriums, canopies, stadiums, and public installations. Designers can combine structural functionality with visual appeal.

Beyond structural advantages, SHS steel sections offer environmental and economic benefits:

Reduced Material Consumption – Hollow geometry requires less steel than solid beams, minimizing resource usage.

Ease of Transport – Lightweight sections reduce fuel consumption and handling efforts during construction.

Recyclability – Steel is 100% recyclable, contributing to sustainable building practices.

Prefabrication Compatibility – Modular SHS frames allow for faster construction, reducing on-site energy consumption and labor.

These factors make SHS steel sections an environmentally responsible choice for modern construction.

To maximize benefits, engineers should evaluate:

Size and Wall Thickness – Determine the load-bearing capacity and span requirements.

Steel Grade – High-grade steel ensures improved strength and fatigue resistance.

Surface Treatment – Galvanization or coating enhances durability in corrosive environments.

Joint and Connection Design – Proper welding or bolting ensures structural integrity.

Compliance with Standards – Ensure SHS sections meet local and international codes such as EN 10210, EN 10219, or ASTM A500.

Careful selection ensures optimized structural stability and longevity for both load-bearing and framing applications.

Square Hollow Structural Sections (SHS) provide a combination of strength, stability, versatility, and aesthetic appeal that makes them ideal for modern load-bearing and framing systems. Their uniform geometry, high torsional rigidity, resistance to buckling, and lightweight nature make SHS sections a practical and efficient choice for engineers and architects seeking to build safe, durable, and visually appealing structures.

Whether for commercial buildings, industrial facilities, residential projects, or architectural designs, SHS steel sections allow for stronger, more efficient, and environmentally conscious construction.

For construction professionals seeking reliable, high-quality SHS steel sections, working with a trusted supplier is essential. www.tjfriendsteelpipe.com offers a wide range of SHS products suitable for various applications, ensuring structural stability, durability, and ease of integration. Exploring their solutions can help optimize your next construction project while maintaining safety, efficiency, and cost-effectiveness.