Views: 199 Author: Site Editor Publish Time: 2025-11-11 Origin: Site

RSH (Rectangular Steel Hollow) and SHS (Square Steel Hollow) tubes are essential components in various industries due to their structural strength, durability, and versatility. These tubes are widely used in construction, infrastructure, machinery, and engineering applications for load-bearing structures, frames, and scaffolding. The production of high-quality RSH/SHS steel tubes involves a sophisticated manufacturing process that requires precise control and advanced technology. The process begins with the selection of high-quality steel and continues through forming, welding, cooling, and surface finishing. Modern production techniques, such as automation and computer numerical control (CNC), have significantly improved the efficiency, consistency, and precision of RSH/SHS tube manufacturing. Understanding these processes is crucial for ensuring that the tubes meet industry standards for strength, safety, and corrosion resistance. This article will explore the manufacturing process and production technologies behind RSH/SHS steel tubes, highlighting the role of innovation and precision in producing high-performance tubes that meet the demands of various structural applications.

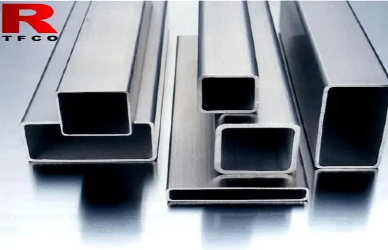

RSH (Rectangular Steel Hollow) and SHS (Square Steel Hollow) tubes are types of hollow structural steel tubing that come in rectangular and square shapes, respectively. These tubes are formed by welding or seamless processes, resulting in hollow sections that are used to provide structural strength in various applications. The hollow nature of these tubes allows them to withstand high levels of stress while keeping weight to a minimum, making them ideal for load-bearing structures. Both RSH and SHS steel tubes are highly regarded for their strength, rigidity, and versatility, which makes them essential in numerous industries.

RSH/SHS steel tubes are widely used across many industries due to their durability and adaptability:

Construction: They are commonly used in building frames, structural supports, scaffolding, and bridges due to their high strength-to-weight ratio, which reduces material usage without sacrificing stability.

Infrastructure: In infrastructure projects like highway guardrails, utility poles, and structural components for civil engineering, RSH/SHS steel tubes provide excellent resistance to forces and environmental factors.

Machinery: These tubes are used in manufacturing machinery and equipment, offering strong structural support for parts that need to bear heavy loads or resist external pressures.

Engineering: In engineering applications, RSH/SHS steel tubes are used for creating frames, beams, and other critical components that require high tensile strength, durability, and resistance to deformation.

The production of RSH (Rectangular Steel Hollow) and SHS (Square Steel Hollow) tubes involves several key steps that ensure strength, durability, and precision. From steel material selection to surface finishing, each stage plays a crucial role in the final product’s performance.

The process begins with selecting high-quality carbon steel or alloy steel, chosen for its strength, weldability, and resistance to corrosion. The type of steel used is based on the application, ensuring that the tubes can withstand the required load and environmental conditions.

The forming process shapes the steel sheets into tubes using hot rolling or cold rolling methods:

Hot Rolling: Steel is heated to high temperatures, making it malleable for shaping. This method is typically used for larger diameter tubes and allows for more flexibility in forming.

Cold Rolling: The steel is shaped at room temperature, providing better precision and a smoother finish. This method is ideal for smaller tubes with better mechanical properties.

The edges of the rolled steel are joined using high-frequency induction welding (HFIW) or electric resistance welding (ERW). These methods involve using electrical currents to heat the edges and press them together, forming a continuous weld. This ensures a strong, durable tube structure.

After welding, the tubes are cooled to solidify their shape. The annealing process may follow, where the steel is heated and then cooled slowly to relieve internal stresses and improve ductility, making the tubes more durable.

Once the tubes are welded and annealed, they are cut to the required length using precision machinery. This step ensures that the tubes meet client specifications and industry standards for length and fit.

The final step is surface treatment to enhance corrosion resistance:

Galvanizing: Tubes are coated with zinc through hot-dip galvanizing, which protects them from corrosion, particularly in outdoor and damp environments.

Painting or Coating: Additional coatings, such as paint or epoxy, may be applied for extra protection against chemicals, moisture, and abrasion.

The production of RSH (Rectangular Steel Hollow) and SHS (Square Steel Hollow) tubes relies heavily on advanced technology and automation to ensure the highest standards of quality, precision, and efficiency. These technological advancements play a key role in producing tubes that meet the rigorous demands of various industries.

Automation has revolutionized the production process of RSH/SHS steel tubes, ensuring consistent tube dimensions, superior welding quality, and overall production efficiency. Automated systems control the processes of rolling, welding, and cutting, significantly reducing human error and variations in tube size. This allows for high-volume production without compromising the integrity of each tube. Additionally, automation optimizes the speed and accuracy of operations, reducing production time and improving output, which is especially beneficial for large-scale manufacturing.

Quality control is essential throughout the production of RSH/SHS steel tubes to ensure they meet the required standards for strength, safety, and performance. The following testing methods are employed during production:

Visual Inspections: The first line of defense in quality control, where the tubes are examined for surface defects such as cracks, welding imperfections, or irregularities.

Dimensional Checks: Precise measurements are taken to ensure the tubes adhere to specified sizes, including wall thickness, length, and external dimensions. Automated systems help ensure these measurements are accurate across large batches.

Mechanical Property Tests: Tests such as tensile strength, hardness, and elongation are conducted to ensure the tubes possess the necessary mechanical properties to withstand stress and pressure in their intended applications.

Non-Destructive Testing (NDT): Techniques like ultrasonic testing, X-ray inspection, and magnetic particle testing are used to detect internal flaws or welding defects that could affect the structural integrity of the tubes without damaging the material.

Computer Numerical Control (CNC) Machines: CNC machines are essential in ensuring high precision during the cutting and shaping processes of RSH/SHS steel tubes. These machines are programmed to follow precise specifications, guaranteeing consistent results for tube lengths, cuts, and shapes. CNC technology allows for customization of tube dimensions, ensuring that every tube meets the exact requirements of the project or application.

Laser Welding: Laser welding has become increasingly popular in the production of high-strength RSH/SHS steel tubes due to its ability to create clean, strong welds with minimal distortion. The focused laser beam melts the edges of the steel to fuse them together, offering greater precision and a higher-quality weld than traditional methods. Laser welding also reduces thermal distortion and stresses in the tube, ensuring the integrity of the weld and the overall strength of the tube.

Modern manufacturing technologies have significantly improved the production of RSH (Rectangular Steel Hollow) and SHS (Square Steel Hollow) steel tubes, offering several key benefits that enhance product quality, efficiency, and sustainability.

Advanced production techniques like CNC machines and laser welding ensure better tolerance, stronger welds, and higher overall quality in RSH/SHS steel tubes. CNC machines provide high precision in cutting and shaping, minimizing variations and ensuring consistent tube dimensions. Laser welding creates clean, accurate welds with minimal distortion, enhancing tube strength and durability. These technologies contribute to the structural integrity of the tubes, making them reliable for demanding applications.

Automation is a major factor in reducing lead times, improving scalability, and meeting the increasing demand for high-performance tubes. Automated systems handle multiple production tasks simultaneously, such as material handling, welding, and cutting, which accelerates the process while reducing errors. This boosts production rates and allows manufacturers to scale production quickly in response to fluctuating market demands, all while maintaining high quality.

Modern technologies also support sustainable production practices. Energy-efficient processes reduce energy consumption, minimizing the carbon footprint of production. Additionally, recycling initiatives incorporate recycled steel into production, conserving natural resources and lowering environmental impact. Waste management systems further enhance sustainability by repurposing scrap materials. These eco-friendly practices help reduce the environmental footprint of RSH/SHS steel tube manufacturing.

Answer: RSH (Rectangular Steel Hollow) and SHS (Square Steel Hollow) tubes are used in construction, infrastructure, machinery, and engineering applications. Their strength, durability, and versatility make them ideal for structural support, frames, scaffolding, and load-bearing functions.

Answer: RSH/SHS steel tubes are typically made from high-quality carbon steel or alloy steel. These materials are selected for their strength, weldability, and resistance to corrosion and other environmental factors.

Answer: In the manufacturing of RSH/SHS steel tubes, high-frequency induction welding or electric resistance welding is used to join the edges of steel sheets. This welding process ensures the strength and integrity of the tubes.

Answer: Surface finishing, such as galvanizing, painting, or coating, enhances the corrosion resistance of RSH/SHS steel tubes. It protects the steel from environmental damage, extends the tube's lifespan, and maintains its structural integrity in harsh conditions.

Understanding the manufacturing process and technology behind RSH (Rectangular Steel Hollow) and SHS (Square Steel Hollow) steel tubes is crucial for ensuring the production of high-quality products that meet the demands of various industries. Advanced technologies such as automation, CNC machines, and laser welding play a pivotal role in enhancing precision, increasing efficiency, and maintaining consistent product quality. These innovations allow manufacturers to meet the growing market demand for structural steel tubes while ensuring durability and performance in critical applications. When selecting suppliers or manufacturers for RSH/SHS steel tubes, it is essential to consider these factors—technology, quality control, and production efficiency—to ensure that the tubes meet the specific requirements of your project and provide long-term value.